1. What is a Long and Thin Shaft?

A shaft with a length-to-diameter ratio greater than 25 (i.e., L/D > 25) is referred to as a long and thin shaft. Examples include lead screws and optical shafts on lathes.

2. Machining Challenges of Long and Thin Shafts:

Long and thin shafts have poor rigidity. During turning, the workpiece is affected by cutting forces, cutting heat, and vibrations, which can lead to deformation. This results in machining errors such as deviations in straightness and cylindricity, making it difficult to meet the required tolerances and surface quality specified in the design. The higher the L/D ratio, the more difficult the turning process becomes.

3. Key Issues in Machining Long and Thin Shafts:

The poor rigidity of long and thin shafts leads to defects such as bending, barrel distortion, polygonal shapes, and bamboo-joint-like deformation during machining, particularly in grinding processes. Generally, in grinding, dimensional accuracy is poor, and surface roughness requirements are high. Moreover, since the workpiece typically requires heat treatment like quenching or tempering, the cutting heat generated during grinding can easily cause deformation. Therefore, addressing these issues becomes critical in the machining of ultra-long and thin shafts.

4. Solutions:

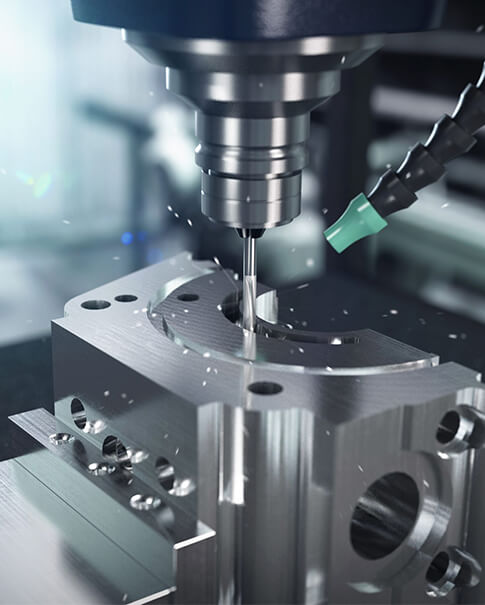

The key to turning long and thin shafts is to prevent bending deformation during machining. This can be achieved through measures in several areas, including fixtures, machine tool auxiliary equipment, process methods, operation techniques, tooling, and cutting parameters. Speed Add Network (速加网) offers unique solutions for the machining of long and thin shafts in terms of process planning, equipment selection, and fixture design. Typically, the machining of long and thin shafts is done using CNC lathes. For shafts with high concentricity requirements, especially when the part design does not allow for turning and reloading, Speed Add Network chooses multi-axis machining equipment (such as four-axis CNC lathes or five-axis Swiss-type automatic lathes) to process the part in a single setup.

STICHWORTE :